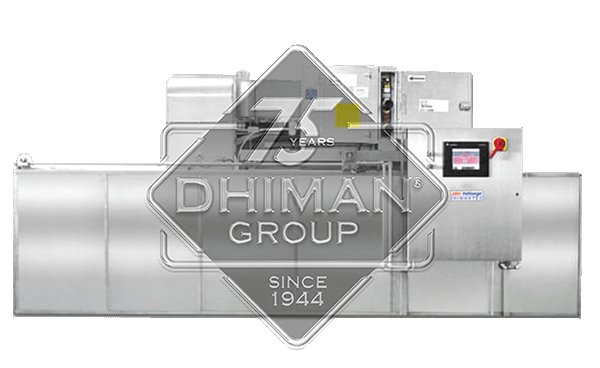

At its core, smart manufacturing is about making factories smarter. It’s like turning your regular, everyday production line into a highly intelligent and interconnected system. The goal is simple – enhance efficiency, reduce waste, and make better, data-driven decisions. Now, imagine injecting this intelligence into the cooling phase of production through the integration of cooling conveyor machines. Discover more about this with DhimanGroup in this informative write-up!

The Basics of Cooling Conveyor Machines

Before we dive into the smart side of things, let’s grasp the basics of cooling conveyor machines. Picture a conveyor belt, but instead of moving products from one point to another, it’s designed to cool them down after a hot and intense manufacturing process. These machines are the unsung heroes behind the scenes, ensuring that your goods come out just right, ready for the next phase or packaging.

Why Smart Manufacturing?

Now, why the shift towards smart manufacturing? Simply put, it’s like upgrading from a flip phone to a smartphone. Smart manufacturing involves the use of advanced technologies like sensors, automation, and data analytics to make the entire production process more efficient and, dare we say, smarter. The same concept applies when we talk about integrating cooling conveyor machines into this system.

How Smart Cooling Conveyors Work?

Imagine a cooling conveyor machine that not only cools your products but also communicates with the entire production line. It knows exactly how many items are coming its way, their temperature, and the desired end result. These smart conveyors use sensors to gather data and make real-time decisions. If a product needs a little more time to cool, it automatically adjusts its speed. It’s like having a conveyor belt with a built-in brain.

Reducing Waste and Boosting Quality

One of the brilliant aspects of integrating cooling conveyor machines into smart manufacturing is the significant reduction in waste. The system ensures that products are cooled precisely to the required temperature, avoiding overcooling or undercooling. This not only prevents unnecessary waste but also enhances the overall quality of the products coming off the line.

Real-Time Monitoring for Precision

In the world of smart manufacturing, information is power. These smart cooling conveyors from DhimanGroup provide real-time monitoring of the entire cooling process. Imagine having a dashboard that shows you the temperature of each product, the speed of the conveyor, and any potential issues. It’s like having a watchful eye on your production line, ensuring everything is running smoothly.

Predictive Maintenance: A Game-Changer

Let’s talk about another game-changer – predictive maintenance. Traditional machines break down, causing unexpected halts in production. Smart cooling conveyor machines, on the other hand, use data to predict when they might need maintenance. It’s like your car telling you it needs an oil change before the engine breaks down. This proactive approach minimizes downtime, keeping your production line humming smoothly.

The Human Touch in Smart Manufacturing

Now, you might wonder, does all this technology mean less need for human involvement? Not at all. Smart manufacturing is about collaboration between humans and machines. While smart cooling conveyor machines handle the nitty-gritty details, human operators bring the creativity, problem-solving skills, and the ability to adapt to unforeseen challenges. It’s a partnership that amplifies the strengths of both.

Cost-Efficiency and Sustainability

Smart manufacturing, including the integration of intelligent cooling conveyors, has a positive impact on the bottom line. By reducing waste, preventing unexpected breakdowns, and optimizing the entire production process, it inherently becomes more cost-efficient. Moreover, the precision in cooling contributes to sustainability efforts by minimizing energy consumption and material wastage.

Challenges and Solutions

Of course, no technological revolution comes without challenges. The integration of smart cooling conveyor machines requires investments in technology, training, and infrastructure. However, the long-term benefits in terms of efficiency, quality, and sustainability often outweigh these initial hurdles. Plus, the technology is evolving rapidly, making it more accessible for businesses of all sizes.

The Future Calls: What’s Next?

As we stand on the cusp of this technological shift, the future looks promising. We can anticipate even smarter cooling conveyor machines that seamlessly integrate with other production processes, creating a holistic and interconnected smart factory. Machine learning algorithms may further enhance decision-making capabilities, making the entire system more adaptive and responsive to changing production needs.

Conclusion: The Smart Path Forward

The integration of cooling conveyor machines into the realm of smart manufacturing is nothing short of a revolution. It’s about making our production processes more intelligent, efficient, and sustainable. As these technologies become more prevalent, businesses that embrace this change are not just staying ahead; they are shaping the future of manufacturing. The conveyor belt system from DhimanGroup has become smarter, and in doing so, it’s leading us towards a new era of production excellence.